Professional industrial coding and marking machines manufacturer

A CIJ printer, also known as a Continuous Inkjet Printer, is a type of printing technology used in marking and coding products. It works by propelling tiny droplets of ink onto the surface of an object, creating characters, logs,date codes, bar codes, QR codes, lot numbers, batch numbers, graphics etc. CIJ printers are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and packaging.

CIJ printers use a continuous stream of ink droplets that are electrically charged. The printer's printhead contains small nozzles that break the ink stream into individual droplets. An electronic control system selectively charges the droplets based on the desired pattern, and then they pass through deflection plates that guide them onto the substrate. The uncharged droplets are recirculated back into the ink supply for reuse.

CIJ printers can mark a wide range of surfaces, including flat, concave, convex, round surfaces. This flexiability of the CIJ printers allow for the marking of various shapes and contours.

Some advantages of CIJ printers include: 1. High-speed printing capability, allowing for fast production lines; 2. Ability to print on curved, uneven, or irregular surfaces; 3. Versatility in printing a range of characters, codes, logos, and graphics; 4. Ability to print on both porous and non-porous materials; 5. Minimal contact with the substrate, reducing the risk of damage to delicate objects;

Yes, CIJ printers can print bar codes and QR codes. Apart from that, CIJ printers are also capable of printing characters, date codes, lot numbers, alphanumeric information, logs, graphics etc. This makes them suitable for product identification, tracking, and traceability purposes across industries.

A laser marking machine is a device that utilizes a focused laser beam to remove or alter the surface of the material, resulting in a visible and permanent date code, bar code, or QR code etc. Laser marking machines vary by the wavelength of light, and different wavelengths are optimized for processing different materials. Typically, there are three types of lasers, the UV laser, the fiber laser and the CO2 laser.

Laser marking machines work by emitting a laser beam through a process called laser engraving or laser etching. The laser beam interacts with the surface of the material, either by melting, vaporizing, or discoloring it, depending on the type of laser and material being marked. The laser marking machine uses precise control and computer-guided movements to create the desired mark, such as texts, logos, bar codes, QR codes, date codes, batch codes, lot numbers or serial numbers.

Laser marking machines are versatile and can mark a wide range of materials, including metals( such as stainless steel, aluminum, titanium, gold, silver, copper etc), plastics, ceramics, glass, wood, leather, paper, and certain fabrics. The suitability of material for laser marking depends on material composition and the specific type of laser used. Usually, fiber laser markers are adopted for marking metallic products such as gold, silver, copper, stainless steel, aluminum and some plastics. CO2 laser marking machines are used to mark non-metallic products such as cardbaord, plastics, wood, ceramics etc. UV laser coders are used for fine marking of elecrical and electronic parts such as PCBs, silicon wafers.

Some advantages of laser marking machines include: 1. High precision and accuracy in creating marks; 2. Non-contact process, minimizing the risk of damage to the material; 3. Permanent and durable markings that are resistant to wear, fading, and solvents; 4. Versatility in marking various materials and complex shapes; 5. Fast processing, especially for small or intricate designs; 6. Environmentally friendly, as it does not require consumables like ink, solvent, or ribbons.

Yes, laser markings are generally permanent and highly resistant to fading, scratching, or rubbing off. The laser removes or alters the surface layer of the material, creating a lasting mark.

1. The type of materials you plan to mark. 2. Required marking speed, and production line speed. 3. Laser power and wavelength suitable for your application. 4. Marking area or working size of the machine. 5. Ease of use and software capabilities. 6. Integration possibilities with existing production processes.

We offer free consultation service to our customers, we also run sample marking for our customers based on their line speed, so as to ensure that the right laser type and laser wattage are selected for our customers' marking application.

Yes, the marking software is free of charge, easy to operate and in English.

The delivery time depends on the specific model and quantity ordered. Usually, we are able to make delivery within 7- 15 days, In cases where special requirements are involved, we will also expedite the process to ensure prompt delivery without any compromise on quality or service.

We offer 1 year warranty for all our CIJ printers, TIJ printer and laser marking machines as well as the spare parts. However, consumables such as CIJ inks, cartrisges, solvents does not fall into the scope of warranty. We also offer online customer service either via whatsapp, wechat, or email, where our engineers provide guidance on how to install, operate, debug, and trouble shoot the printers and marking machines.

A fiber laser engraving machine, also known as a fiber laser marking machine or fiber laser engraver, is a type of laser coding technology apoted to mark or engrave various materials. It utilizes a fiber laser source to generate a focused laser beam to create permanent marks such as dates, QR codes, bar codes etc on packages or products. A fiber laser coder is typically used to mark metallic products such as gold, silver, copper, alumimum, stainless steel, iron etc. However, a fiber laser coder is also capable of marking some plastics.

A flying laser marking machine, also known as a flying laser coder or flying laser marker, is a type of laser system, that uses a laser source, either UV, fiber or CO2, to create precise and permanent marks or engravings on various materials. The term "flying" refers to the machine's ability to mark objects while they are in motion, typically on a conveyor belt or automated system.

An online TIJ (Thermal Inkjet) printer is a type of inkjet printer that uses thermal inkjet technology to print high-resolution images and text onto various surfaces. TIJ printers are often used in industrial applications, such as product packaging, labeling, and coding. The term "online" TIJ printer generally refers to a printer that is integrated into a production line or other automated system. They typically use replaceable ink cartridges, making ink maintenance and replacement relatively easy.

A laser marking machine is known for its reliablity, and depending on its laser source, the serive life varies from 20 000 hours to 100000 hours

Product features

1. Easy to operate software with 8-inch smart touch screen control panel.

2. Supports sensor trigger mode (sensor head) and external I/O trigger mode (other device signals).

3. Built-in red light indicator preview component to preview and display the coding content.

4. Floor-standing mobile bracket supports front and rear adjustment (coding position adjustment) and up and down adjustment (working distance adjustment)

Technical specifications

| Laser power | 3W @30KHz | 5W @30KHz |

| Laser wavelength | 355nm | |

| Frequency | 20-150 KHz | |

| Marking speed | <6000mm/s | |

| Marking area | 70mm×70mm-300mm×300mm | |

| Touch screen size | 8inches | |

| Code type | texts, digits, date codes, lot number, bar codes, QR codes, graphics etc | |

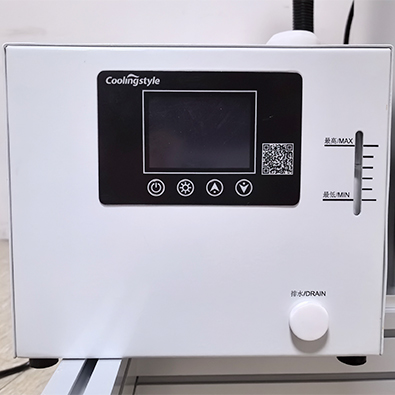

| Cooling method | Water cooled | |

| Communication | TCP/IP and RS232, Modbus-RTU / TCP | |

| Electrical requirements | 110V/220V 50Hz | |

| Power consumption | 800W | |

| Dimensions | ||

| Laser unit | 650mm*160mm*150mm / 7.5kg | |

| Control unit | 345mm*160mm*260mm / 6.2KG | |

| Chiller | 345mm*248mm*215mm / 10.5KG | |

| Bracket | 656mm*550mm*1455.8mm | |

Field lens parameters

Lens | Marking Area(mm*mm) | Work distance(mm) |

| 355-100-70 | 70×70 | 135 |

| 355-130-90 | 90×90 | 165 |

| 355-160-110 | 110×110 | 218 |

| 355-208-130 | 130×130 | 256 |

| 355-210-150 | 150×150 | 255 |

| 355-254-175 | 175×175 | 305 |

| 355-290-200 | 200×200 | 350 |

| 355-330-220 | 220×220 | 400 |

| 355-380-250 | 250×250 | 435 |

| 355-420-300 | 300×300 | 570 |

| Notes: Special requirements for work distance and marking area can be customized. | ||

Applications and samples

Applicable to most plastics,leather, glasses, ceramics, jade,crystal, and metallic coatings.

Product details

Lens

Laser source

Chiller front

Chiller back